TEI performs structural material evaluations of various building components and bridge structures. At TEI, we understand how to work with the challenges presented by older structures, such as missing or incomplete original documents, unknown building materials or site conditions, undocumented building changes, structural deterioration, damage from previous events, inaccessibility to certain areas, and preservation of historical elements.

Numerous destructive and non-destructive methods are used to assess and evaluate the structural materials in question. Using our expertise, we are able to determine the correct approach to best serve our clients’ needs.

Once a concrete floor, wall or ceiling is in place, it is difficult to know exactly what is going on inside the concrete without specialty equipment. Scanning the concrete using GPR can avoid costly mistakes on the job site when navigating through previously installed concrete elements. Using GPR, TEI can map out steel reinforcing, conduits, post-tension cables, voids, and determine the concrete’s thickness.

Concrete coring is a destructive method of evaluating concrete structures by extracting specimens for laboratory testing and evaluation. TEI performs concrete coring on both vertical and horizontal structures in accordance with ASTM C42, “Standard Test Method for Obtaining and Testing Drilled Cores and Sawed Beams of Concrete.” Using a Pachometer or GPR, TEI can map out the reinforcing steel prior to coring to either avoid it while coring or expose it for measuring.

Common laboratory testing performed includes compressive strength, chloride ion content, petrographic analysis, splitting tensile, chloride penetration resistivity and more.

Swiss Hammer testing is a nondestructive method commonly used for estimating the compressive strength of in-place concrete. Developed in 1948 by a Swiss engineer named Ernst Schmidt, the device measures the hardness of concrete surfaces using the rebound principle. TEI performs Swiss Hammer testing in accordance with ASTM C805, “Standard Test Method for Rebound Number of Hardened Concrete.”

Windsor Probe testing is a minimally destructive method of testing the strength of concrete. It is performed by penetrating the surface of the concrete with a hardened steel probe with a blunt conical tip. The depth of penetration is measured and the strength of the concrete is taken from a table provided by the manufacturer. TEI performs Windsor Probe testing in accordance with ASTM C803, “Standard Test Method for Penetration Resistance of Hardened Concrete.”

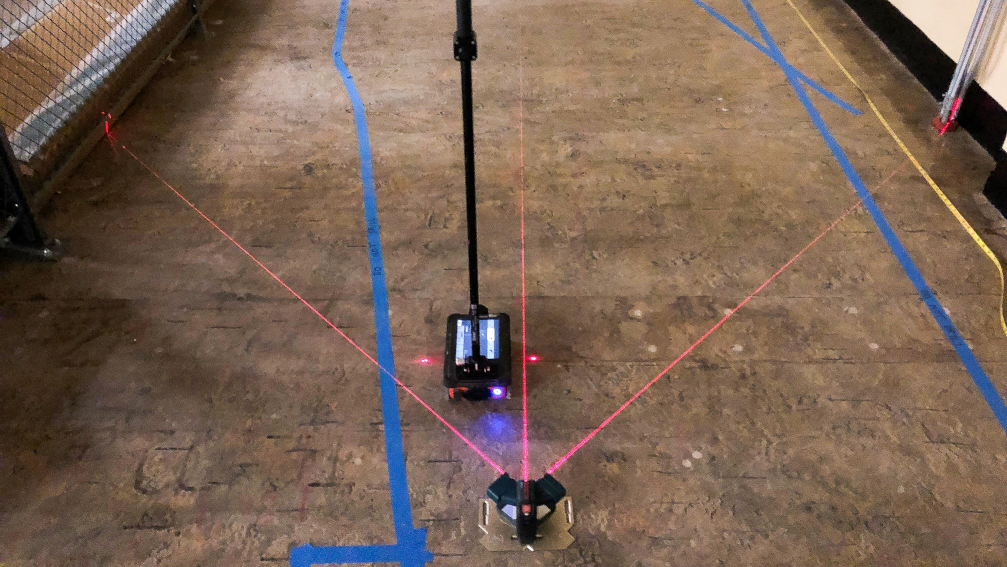

Ultrasonic pulse velocity (UPV) testing is an in-situ, nondestructive test used to check the quality of concrete and natural rocks. In this test, the strength and quality of concrete or rock is assessed by measuring the velocity of an ultrasonic pulse passing through a concrete structure or natural rock formation. TEI performs UPV testing in accordance with ASTM C597, “Standard Test Method for Pulse Velocity through Concrete.”

Determining the grade of steel you’re dealing with in older structures can be challenging. TEI performs in-situ steel coupon sampling for metallurgical testing of bridge structures and structural members of buildings. Coupon samples for metallurgical testing are generally prepared and tested by machining the coupons into testing specimens in accordance with ASTM A370, “Standard Test Methods and Definitions for Mechanical Testing of Steel Products.” Standard tests performed include, tensile, yield strength, % elongation, and modulus of elasticity.

Utilizing a video borescope during a structural material assessment allows TEI to investigate inaccessible areas of buildings or subgrades with minimal damage to the structure. The borescope camera provides a real-time view of the area in question and can help verify or quantify void areas under slabs, obstructions in piping, etc. The borescope inspection allows both video and still image capture for subsequent analysis and reporting.

TEI performs asphalt sampling using wet core drilling methods to extract asphalt specimens for laboratory testing. After extraction, the underlying soil materials may also be sampled at each encountered stratum and returned to the laboratory gradation testing. Whether you need to check asphalt thickness or require a full suite of laboratory testing, TEI has you covered.